About a Mold/Dies

From Japan Diecasting Association

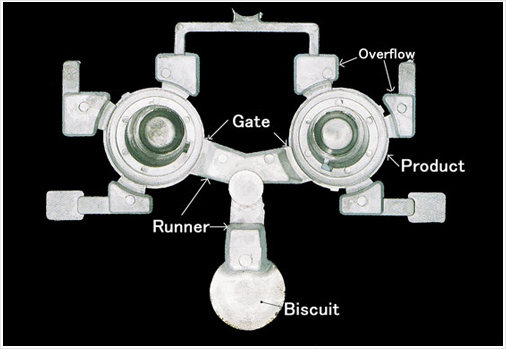

Die cast product {Taking out from mold 2 pieces in a cavity}

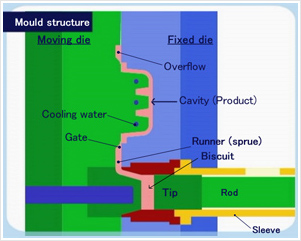

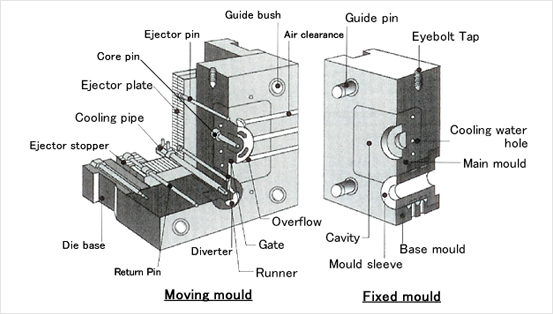

Die casting mold

Die casting mould

| Terms | Description | |

|---|---|---|

| 1 | Fixed Mould | Above drawing right half part. Mould sleeve attaches to cast molten metal in. |

| 2 | Moving Mould | Above drawing left side half. Attaching to movable platen of die casting machine. Usually, casting product clings to this side. |

| 3 | Nest mould (Main mold) |

It does not make cavity in a mould itself directly, but it uses a high quality material only around cavity as a nest so that it can save material cost of mould. |

| 4 | Base mould | Base of mould to fit a nest mould in.Material of nest mould would be high quality material of which high heat-resistance, high corrosion-resisting, high thermal conductivity steel, but material of base mould would be conventional, moderate steel. |

| 5 | Ejector Pin | Ejector pin a bar which is used for pushing a cast product out. |

| 6 | Core | A Mechanism to make holes into a cast product, one method of core is that use moving platen opening movement, another is that use hydraulic cylinder. |

| 7 | Core pin | A bar to make hole into cast product. Every cast cycle it is pulled out from clinging cast product, it needs strength and durability. |

| 8 | Gate | Place just before cavity where molten metal flow through runner way into cavity. It usually narrows to adjust the speed and speed of metal flow which has a great iinfluence on the casting quality. |

| 9 | Biscuit | When plunger tip injects molten metal into cavity, plunger tip works to give pressure to molten metal in a cavity. The place just before plunger tip where must be solidifed the last. |

| 10 | Overflow | The part to store dirty molten metal which runs ahead, when molten metal injected into cavity with high speed and pressure. And it uses to bring metal flow into an edge and a corner of product. |

| 11 | Gas vent | Thin vent space to let air or gas out of cavity. It is usually about 0.1mm thick and places at a cavity directly and also the end tip of overflow. |