About a Cold Furnace&Materials

List of Furnace Makers

- DAIKI Aluminium Industry Co.,Ltd.

- Hirohata Furnace Co.,Ltd.

- Meichu Co.,Ltd.

- TOKAI Corporation

- Tokyo Furnace Industry Co.,Ltd.

- Sanken Sangyo Co.,Ltd.

- Nikkan Indutrial Furnace & Engineering

- Shoei MFG Co.,Ltd.

- Iwabuchi Furace

- Ceramic Industry Co.,Ltd.

- Hokuriku Techno Co.,Ltd.

TOKAI AL-KEEP

![]()

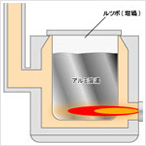

Furnace can be divided into 2 kinds. One is crucible furnace and the other is reverberatory furnace.

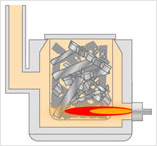

Crucible furnace is that it uses crucible (melting pot) to melt metal such as aluminum or zinc. For instance, putting aluminum ingot in a pot then like a cooking stove heat it to melt the solid aluminum. Crucible( melting pot ) is made of graphite or cast Iron.

Reverberatory furnace is structured by refractory such as firebrick or ceramic fiber brick and it is covered by steel plates. Metals such as aluminum are heated by flames and radiation heat and then it melts down in a furnace floor directly.

Crucible furnace is suitable for casting small quantity, it is very easy to change material, merely changing its crucible to another crucible . If the factory tend to change casting material friquently, crucilble furnace is very convenient.

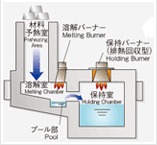

Reverberatory furnace is not suitalbe to change materials frequently, because the metal in a furace directly stored in the inside wall and inner floor, it is quite difficult to take out all the materials completely. However, reverberatory furnace can supply molten metal continuously and it can easily stabilize temperature of molten metal, because it usually has 2 inner rooms, one is for melting another is for holding.

Crucible furnace melts the metal(such as aluminum) in a crucible. It is no worry that if a casting machine uses only small quantity of moulten metal. However if a casting machine operates long time and use a large quantity of moulten metal, it must be put new ingot into the crucible so that molten metal does not run out. When adding new ingot into crucible, the temperature of the moulten metal drops and that is no good for quality of casting.

There are two types of crucible, one is made of cast iron, another type is made of graphite. Cast iron type is easy to use as long as coating anti-collosion solvent, it lasts some years. But Graphite crucible needs to be used carefully, because it is fragile and easily broken. Graphite crucible does not need for anti-corrosion coating because its material has itself the property of anti-corrosion against moulten metal.

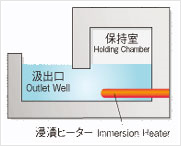

Reverberatory furnace as shown on the left images is called "Melting and holding furnace". It usually have two rooms inside, one is for melting, another is for holding.

It is efficient to keep the temperature of molten metal, because solid ingot is first melted in a melting room and then the liquid comes to holding room. The temperature of holding room is relatively stable. This kind of furnace is suitable for the factory which operates long time continuously.

As shown the left drawing using a round table, put two or three crucible furnace on, then using the furnace by turn.

While using one furnace, operator can melt new ingot and clean the molten metal. Before one furnace running out the molten metal, it can change to another one which is cleaned and keeps required temperature.

This furnace is quite suitable for quality casting which requires severe material quality.

The left is a immersion heater type. Ordinary furnace usually use burner to heat the molten metal. This uses immersion heater as left drawing, heating the molten metal directory. It is quite efficient, comparing with burner because its frame dose not touch the material directory, it prevents over-heat and generated less H2 gas.

Aluminum alloy for diecasting

As diecasting metal, there are Aluminum alloy, zinc alloy, magnesium alloy, yellow-copper(brass) alloy, copper aloy.

Aluminum alloy is the most popular in use, because of its excellent features such as light weight, anti-corrosion, less age-related deterioration. Aluminum alloy accounts for about 95% among all diecasting alloy metals.

Following is the table of constituent elements of aluminum ally for diecasting.

Aluminum alloy can be divided mainly two groups, silicorn group (Al-Si group) and Magnesium group(Al-Mg group). Al-Si group can be yet divided; Al-Si group(ADC1), Al-Si-Mg group(ADC3), AL-Si-Cu group(ADC10,ADC12), Al-Si-Cu-Mg group(ADC14). And Al-Mg group can be also divided ;Al-Mg group(ADC5)and Al-Mg-Mn group(ADC6).

- ADC1, ADC1C, and ADC2 are eutectic alloy that contain 11 - 13% of silicon. It is excellent in metal flow thus good for casting, it is hard to be fragile when heated, and

excellent corrosion resistance. Stress-resistans is a little low. It is suitable for large products which is difficult for its metal flow, such as thin and large complicate shape product.

ADC2 is excellent in anti-corrosion character and toughness character. - ADC7 is a Al-Si eutectic alloy, casting temperature is high thus difficult to cast, but the property of toughness and caulking are excellent.

- ADC3 contains Si element 9 -10%, and Mg element 0.5%. Its stress-resistance and shock-resistant count are high. As for anti-corrosion character is as good as ADC1. It is difficult to cast but it suits to casting products like covers, cases or cap which need the property of stress-resistance and high shock-resistant count.

- ADC5 and ADC6 contain many Mg element,so that its anti-corrosion property is superior. Shock resistant count and elongation count are high, but they are very difficult to cast. ADC5 contains more Mg than ADC6, thus anti-corrosion property of ADC5 is superior to ADC6. Therefore, ADC5 is harder to cast than ADC6. ADC5 and ADC6 are suitable for products which are used ocean ships or vessel or outdoors that are required anti-corrosion property, and for products which needs high shock resistant count and high elongation count.

- ADC8 is Al-Si-Cu-Mn group, its strength is higher than ADC10, but it is more difficult in casting than ADC10.

- Al-Si-Cu group of ADC10, ADC10Z, ADC11, ADC12, ADC12Z are relatively easier to cast and their mechanical property is excellent, furthermore they are very good in machinability. These material account for 90% of all aluminum diecasting products in Japan. As for uses, they are used all general product parts which is required no severe performance. ADC10Z and ADC12Z is allowed to contain ZINC as an impurity maximum 3%, comparing with ADC10 and ADC12 they are not as good in property of anti-corrosion and casting. ADC11 and ADC10 is similar in quality.

- ADC14 (hypereutectic Al-Si group) is especially superior in anti-abrasion property. it is easy to cast and less thermal expansion.

- Pure aluminum group is excellent in electrical conductivity, it is usually used for rotor casting which is covering iron core with aluminum.

From diecast technician handbook